Supply Chain

Suppliers are one of Wellell’s key stakeholders. Upholding the principle of “cooperation and co-existence,” Wellell continuously maintains mutually cooperative relationships with upstream and downstream partners in the supply chain. The Company aims to create sustainable value together with its supplier partners and fulfill its corporate social responsibilities.

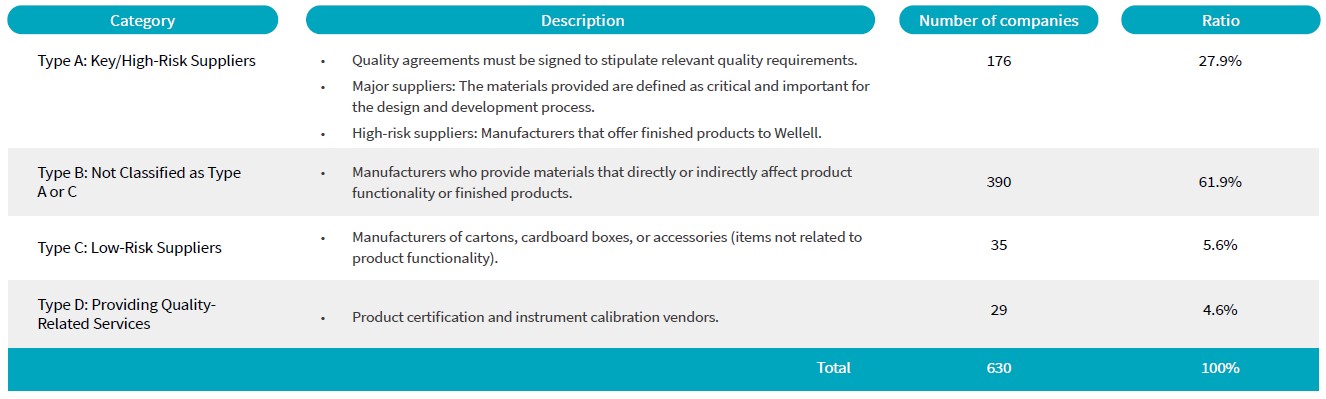

Wellell has formulated the Procurement Operations Management Measures and Procurement Operations Standards as the basis for supplier management. The content of these documents includes mechanisms for supplier selection, standards for the management of supplier classification, and standards for supplier evaluation. Additionally, Wellell categorizes its suppliers to ensure that the goods provided comply with regulations. The Company also requires key/high-risk suppliers to sign quality agreements to ensure that the quality of medical equipment products, which are subject to strict regulatory controls, meets both regulatory requirements and Wellell’s high quality standards.

To counter risks that could potentially disrupt the supply chain and make key raw materials difficult to obtain, Wellell not only maintains stable friendly relationships with suppliers but also closely monitors the supply status and inventory levels of critical materials. In addition, for materials with long lead times, Wellell provides suppliers with estimates of required quantities to help them make appropriate supply arrangements, thereby reducing the risk of insufficient supply.

Supplier Types

Local Procurement

When selecting suppliers, in addition to considering specifications and source of supply restrictions, Wellell also tries to increase the ratio of localized procurement as much as possible. Among regular trading suppliers, the ratio of localized procurement in Taiwan is approximately 93.8%. At the same time, Wellell also follows various international regulations and guidelines, including RoHS (Restriction of Hazardous Substances Directive) and REACH (Regulation on the Registration, Authorization, and Restriction of Chemicals). During the selection process for parts and materials, suppliers are required to pass relevant tests and attach certificates or sign affidavits. This is done not only to avoid harm to users, but also to reduce the impact on the environment.

-

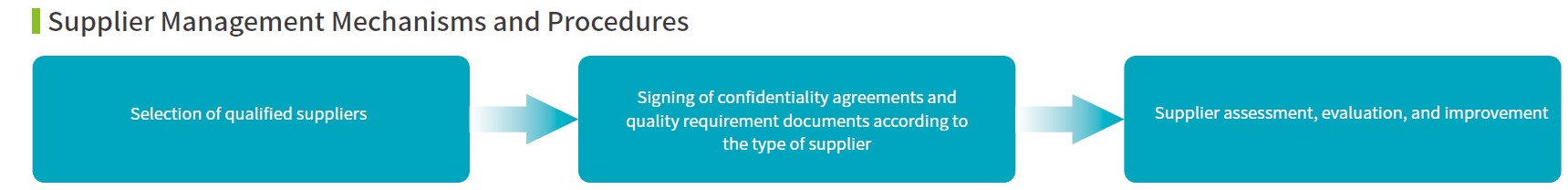

Selection of qualified suppliers and signing of confidentiality documents

After identifying potential suppliers that meet the requirements, Wellell evaluates them based on the multiple aspects of MEQCD (management, environment, quality, cost, and delivery). Qualified suppliers are selected according to their score. At the same time, Wellell requires its suppliers, categorized into four different types, to sign confidentiality agreements, quality agreements, and affidavits on the non-use of hazardous substances (type A suppliers). -

Supplier assessment, evaluation, and improvement

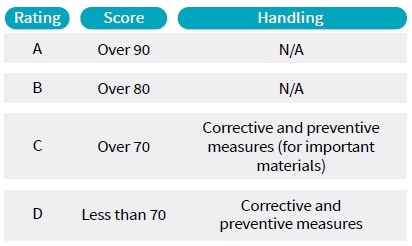

Assessments: Once deemed as qualified, suppliers must undergo an assessment every six months. The assessment focuses on quality and delivery times. Wellell requires suppliers who score less than 80 in the assessment to improve and take corrective and preventive measures. If the improvements are ineffective, the supplier is reported for removal from the list of qualified suppliers.

Regular evaluations: Annual evaluations are conducted by selecting evaluation targets and formulating plans, which are then executed on a monthly basis. The evaluation targets are mainly the key suppliers mentioned above (type A suppliers), followed by those who have changed their manufacturing location or added new equipment. If the result of the evaluation is unsatisfactory, the corrective and preventive action process is initiated and the manufacturer is required to make improvements. If the improvements are ineffective, the supplier is reported for removal from the list of qualified suppliers. In 2024, a total of 32 items divided into 5 categories were evaluated, with a total of 25 suppliers being scrutinized. All suppliers were deemed qualified.

Supplier Sustainability Evaluation

In addition to management of suppliers’ performance and capabilities, Wellell has gradually incorporated requirements for suppliers to implement ESG practices into its procurement procedures. Since 2024, the Company has established the Supplier Social Responsibility and Business Ethics Statement, and suppliers with transaction records over the past two years will be required to sign it. It is expected that 95% of suppliers will sign it in 2025. Through the signing of the statement, suppliers are required to comply with standards in areas such as health and safety, labor and human rights, environmental protection, and business ethics, and fully comply with the laws and regulations of the countries/regions where they operate.

ESG Evaluation Items and Scoring Principles

Through the Supplier Corporate Social Responsibility Checklist, the suppliers should evaluate their social responsibility practices by themselves. Meanwhile, Wellell conducts on-site evaluations and reviews, and scores based on actual implementation results to establish a standardized review mechanism.

Scoring Items: including four items: health and safety, labor and human rights, environment, and business ethics.

Scoring Instructions:

5: With complete processes and 100% implementation records

4: Approximately 80% of processes available or approximately 80% implemented

3: Approximately 50% of processes available or approximately 50% implemented

2: Approximately 30% of processes available or approximately 30% implemented

1: Less than 30% of processes available

0: No processes or implementation records

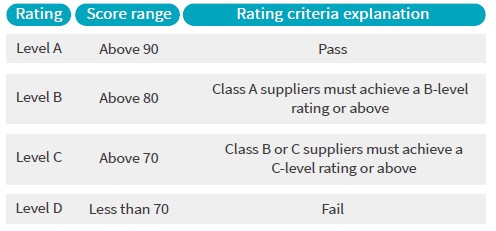

Rating criteria:

Corrective measures for abnormalities

In the Corporate Social Responsibility Checklist, if the rating is Level D (70 or below, including Level D) or if a Class A supplier is rated Level C or below (including Level C), an “Abnormality Correction Action Form” will be issued, and the supplier will be notified to respond with corrective measures. The re-evaluation period is 3 months, during which procurement may continue; if the re-evaluation results remain Fail, the procurement department manager will report to the monthly manufacturing supply chain meeting to decide whether the supplier is delisted or conditionally monitored.

Driving Sustainable Supply Chain Transformation

In response to the global transformation trend toward net-zero emissions, Wellell actively responded to the government programs, and participated in the “Large-Lead-Small Manufacturing Low-Carbon and Intelligent Upgrade Transformation” project launched by the Ministry of Economic Affairs in 2024. Leveraging its corporate influence, Wellell has proactively gathered four supplier partners to jointly pursue intelligent upgrade and transformation.

Through project resources, Wellell and its supplier partners are enhancing intelligent process, integrating information systems, and achieving low-carbon benefits through intelligent operations to address the future trends and demands of digital transformation in manufacturing industry. In 2024, Wellell and its supplier partners completed intelligent diagnosis and preliminary transformation evaluation, and gradually replaced with intelligent manufacturing equipment, information security protection systems, and intelligent factory monitoring systems to improve production efficiency and optimize resource utilization while making the production process more energy-efficient. In 2025, Wellell will continue to collaborate with its supplier partners to build a more resilient, efficient, and sustainable supply chain system through intelligent upgrades.