Procare Auto G3 & Procare Auto Link G3

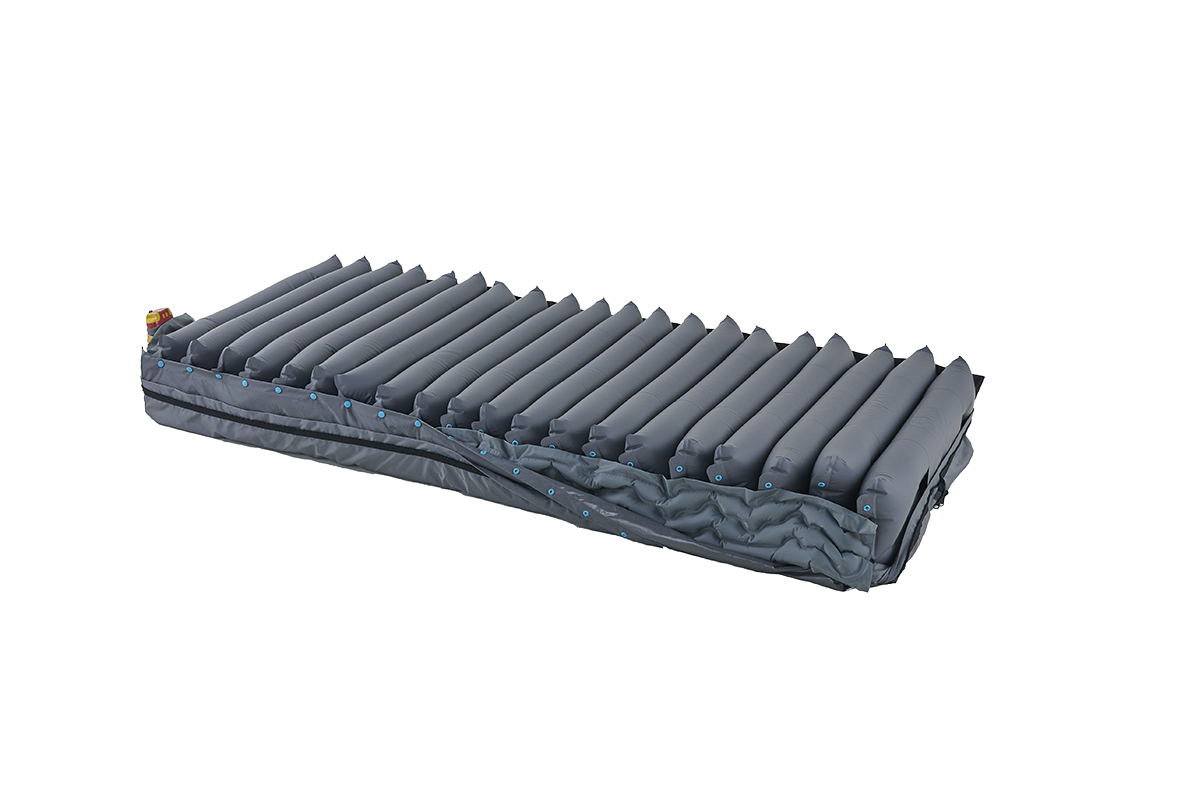

Hospital Air Mattress for BedsoresFor High to Very High Risk

Maximize the efficiency of clinical workflow with digitalized automation

Abbreviation: PI, pressure injury

Procare Auto G3 and Link G3 not only enhance patient safety and reduce caregiver workload in PI prevention, but also address key challenges faced by rental service providers. Through innovative technology, they streamline the air mattress supply process to improve logistics efficiency and service quality.

*Situation of inefficiencies in the support surface supply process: (1) The duration of mattress preparation affects the waiting time of the patient in hoist, which increases the risk of pressure injuries during transfers. (2) High service and maintenance labor costs. (3) Low utilization rates in the mattress rental business

With the implementation of Procare Auto G3 & Link G3, it can shorten the waiting time for mattress preparation, reduce CPR preparation time, and increase service efficiency. Moreover, through the advantage of wireless data transfer function, the system is not only embedded with real-time warning to improve troubleshooting efficiency, but also integrated with digitalized asset number to help streamlining tracking and usage analysis.

*Internal research survey analysis and testing report

Enhance Caregiver Efficiency

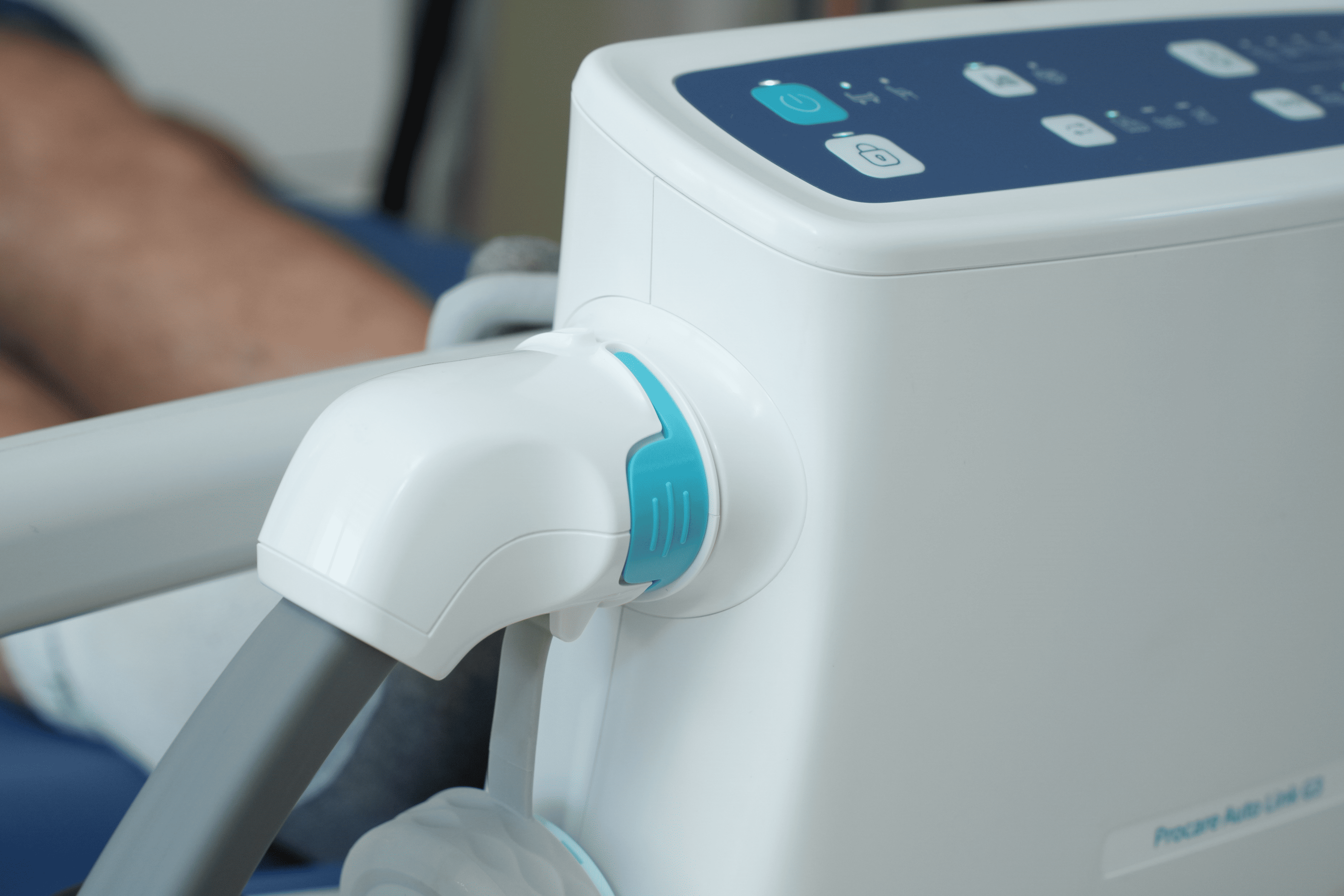

Pump's Twin-head compressor provides high flowrate to inflate the mattress within 11 minutes, improves usage hours, and operates at 22 dBA.

Mattress & Cushion Integration

The pump can be shared between the mattress and cushion, with automatic recognition for seamless system operation.

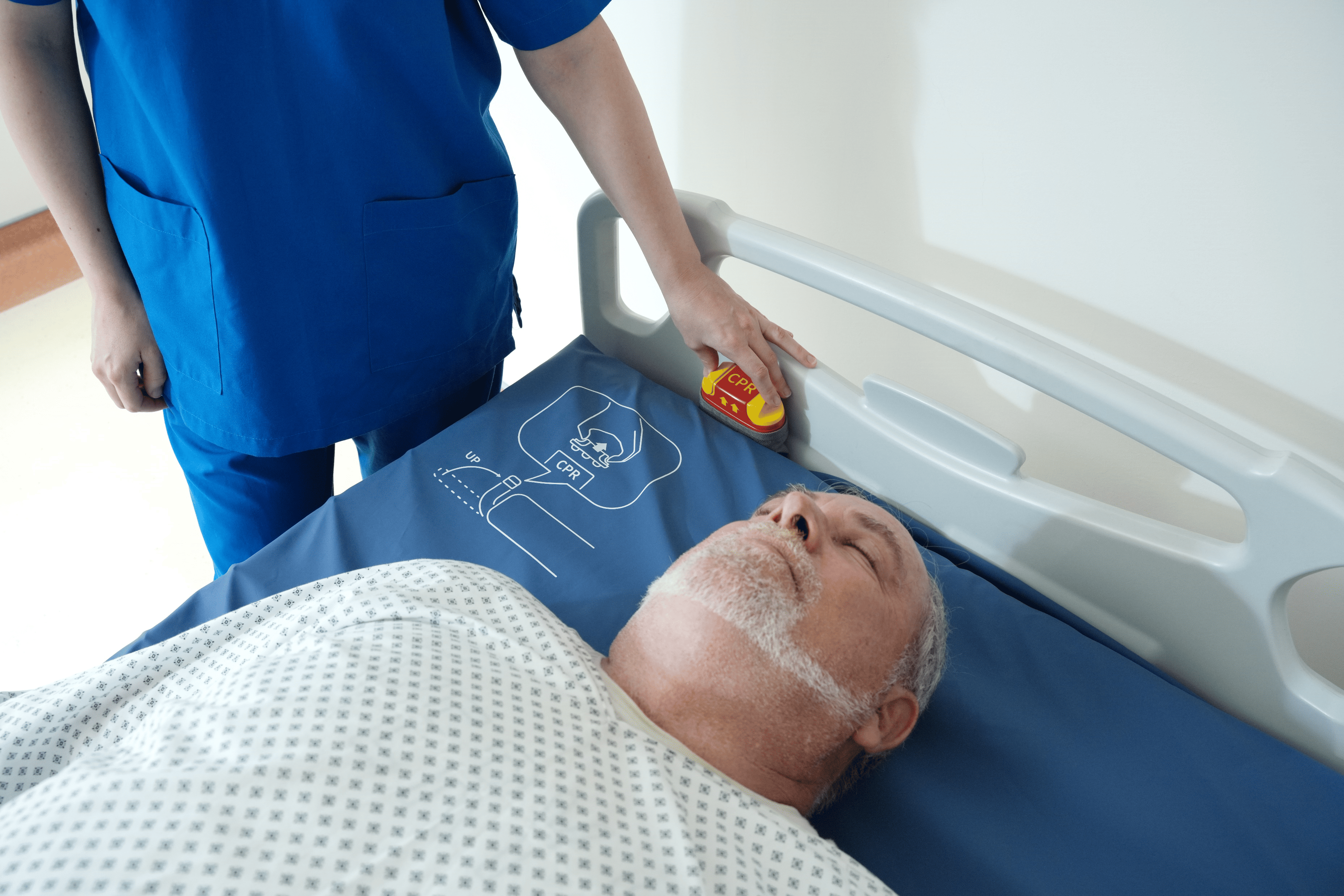

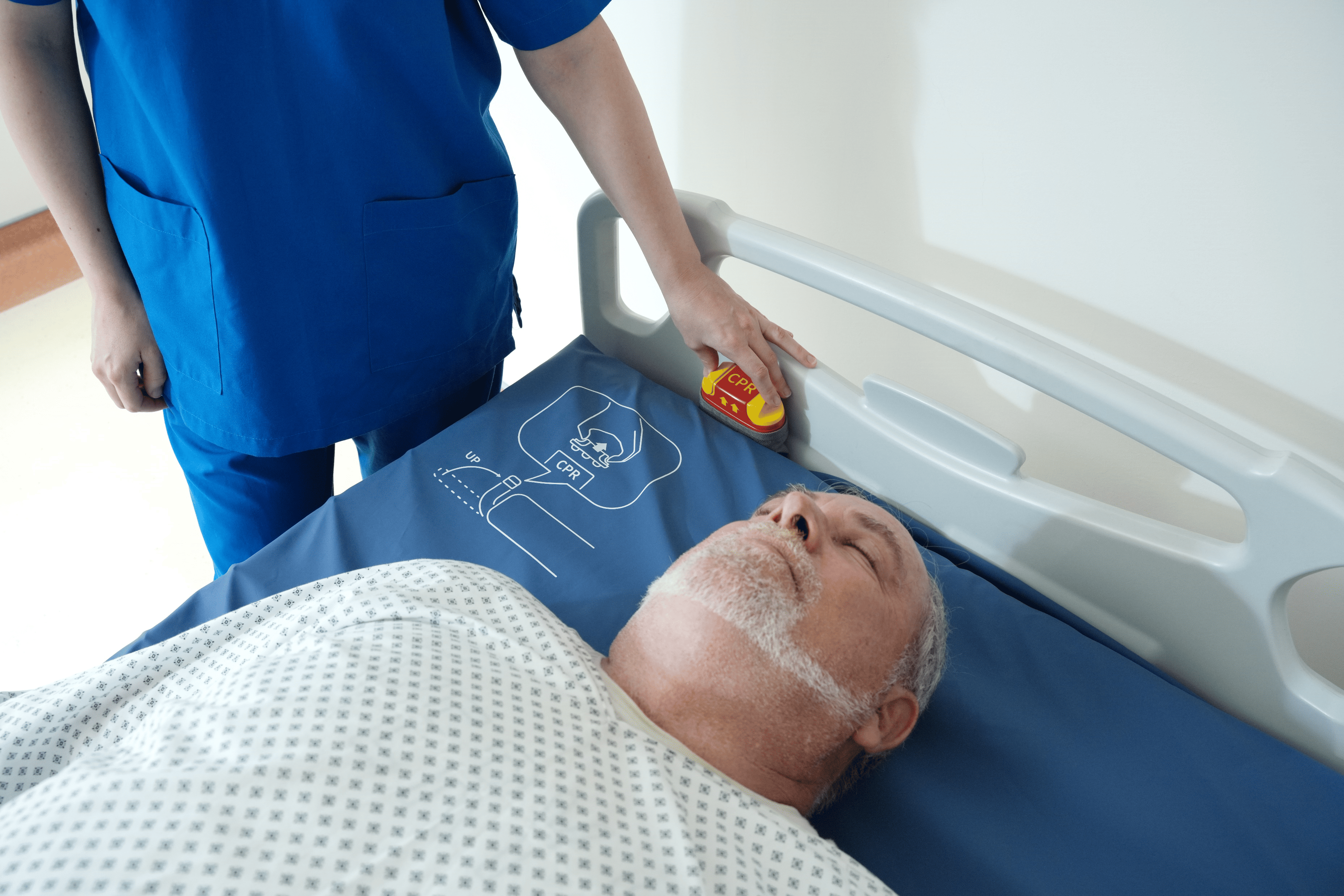

Faster CPR Preparation

Press-Aid CPR Valve located at head-end, featuring high visibility and easy access. The press-to-release design performs quick deflation within 10 seconds.

Easy Maintenance & Durable Design

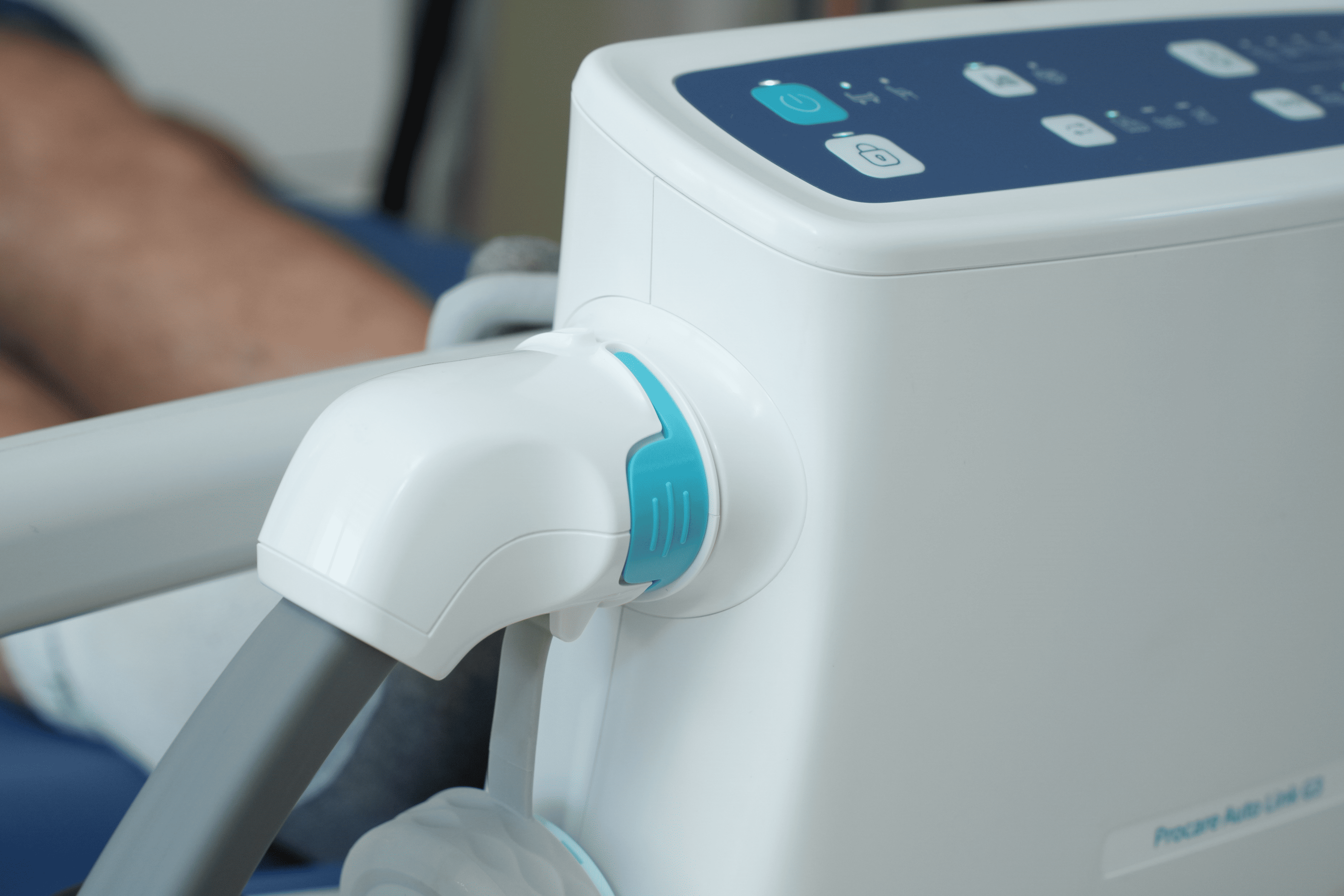

More durable fuel nozzle-style quick connector with an easy-to-clean rectangular air hose design, supporting durability and infection control in clinical settings. FlexVent (Non-PVC air tunnels) reduces packaging volume for storage efficiency. Color-coded A/B snap-on tubes allow quick replacement.

| Procare Auto G3 & Procare Auto Link G3 | ||

|---|---|---|

| Mattress Dimension (L x W x H ) | 80 x 36 x 8 in | 2000 x 800-900 x 200 mm |

| Mattress Weight | 22.0 lb | 10.0 kg |

| Maximum Patient Weight | 550 lb | 250 kg |

| Pump Dimension (L x W x H ) | 12.7 x 5.2 x 10.4 in | 323 x 130 x 265 mm |

| Supply Voltage | 110-240 V / 50-60 Hz |

|

Enhance Caregiver Efficiency

Pump's Twin-head compressor provides high flowrate to inflate the mattress within 11 minutes, improves usage hours, and operates at 22 dBA.

Mattress & Cushion Integration

The pump can be shared between the mattress and cushion, with automatic recognition for seamless system operation.

Faster CPR Preparation

Press-Aid CPR Valve located at head-end, featuring high visibility and easy access. The press-to-release design performs quick deflation within 10 seconds.

Easy Maintenance & Durable Design

More durable fuel nozzle-style quick connector with an easy-to-clean rectangular air hose design, supporting durability and infection control in clinical settings. FlexVent (Non-PVC air tunnels) reduces packaging volume for storage efficiency. Color-coded A/B snap-on tubes allow quick replacement.

Advantages of using Procare Auto G3 & Link G3

For Patients:

- Fast mattress inflation shortens mattress preparation times and less waiting time for patients to be suspended in a hoist can help reduce the risk of pressure injuries.

- Minimizing CPR preparation time to optimize the emergency process.

- The system has an instant alarm function, which helps to quickly eliminate abnormalities and improve response speed and safety.

For Caregivers:

- The mattress preparation time is shortened, which effectively improves work efficiency and reduces manpower pressure.

- The system's intelligent warning and digital tracking functions help caregivers understand device status more quickly and reduce manual inspections on troubleshooting.

For Service Providers:

- Easy maintenance and faster assembling process that reduce labor costs for repair and service.

- Providing real-time tracking data for inventory management, improving the utilization rate of mattress rentals.

- Improve overall logistics efficiency and service quality and enhance operational competitiveness.

The seat cushion is for add-on purchase only, which will not come with the pump and mattress.

Link G3 works the same as G3 but offers wireless data transfer function that integrates with cloud service platform for device management, which enables real-time tracking for troubleshooting and optimizing the asset utilization analysis process.

Both systems have Alternating (ALT) / Continuous Low Pressure (CLP, Static) / Alternating Low Pressure (ALP, Sleep Mode) / Max Firm

The top cover is made with 4-way stretch Polyurethanes (PU) and featured as Titanium-based protection, preventing allergies and enhancing infection control, while meeting the highest sanitation standards.